Ground thermal insulation is an important factor during cold room construction. There are differences methods for ground thermal insulation practices among large, medium and small cold room.

For small cold room

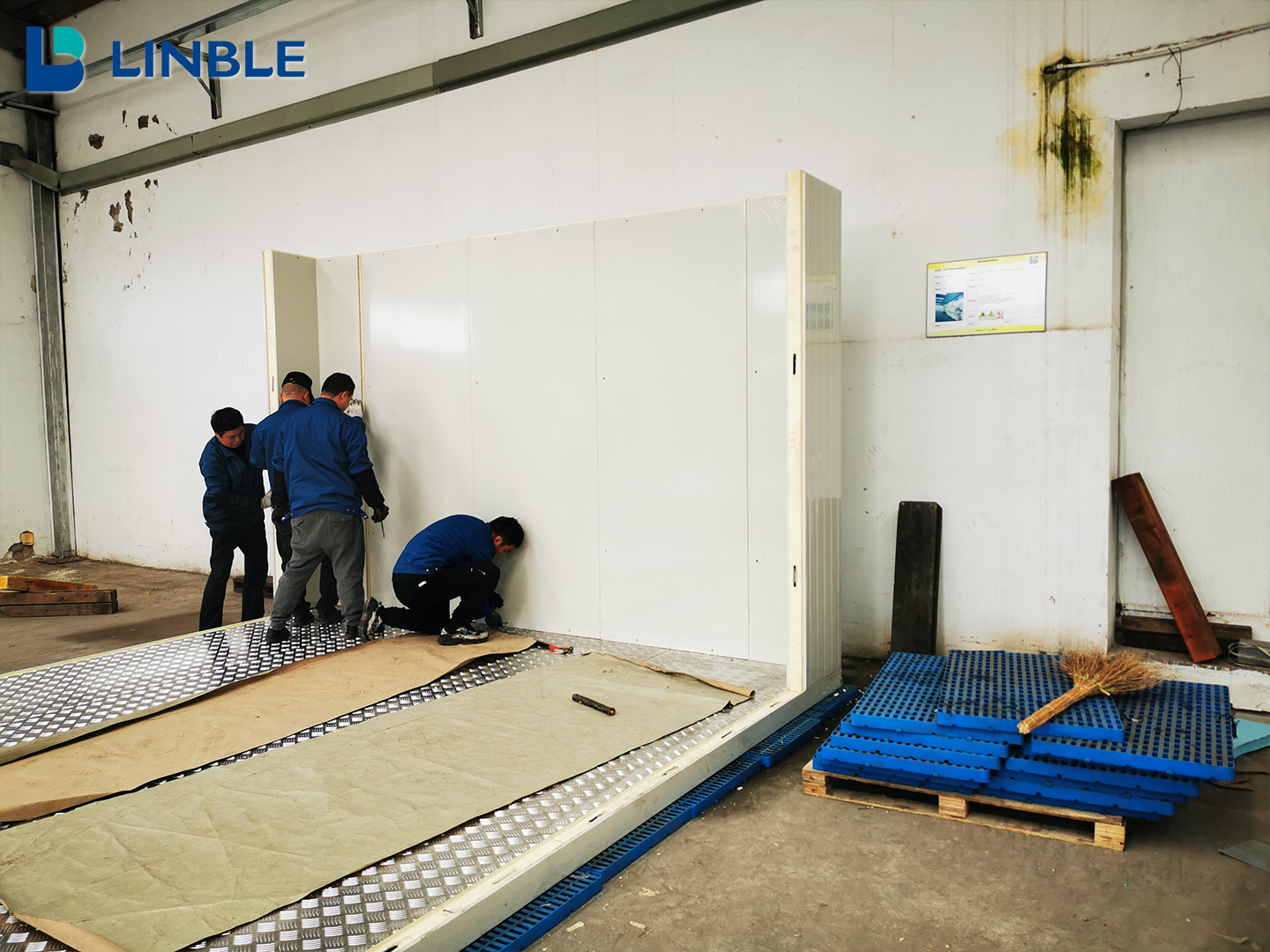

It is relatively simple to construct ground thermal insulation for small cold room. Because there is no special requirement for load-bearing, polyurethane sandwich panel is usually used. If goods are heavy, we can use embossed aluminum steel on floor panel to prevent the damage.

For medium cold room

The ground thermal insulation of medium cold room is more complicated than small cold room. The better way is to use XPS panel to lay the ground, lay moisture-proof and vapor-proof material on the top and bottom of XPS panel. And then pour concrete or reinforced concrete.

For large cold room

Large cold room needs more ground insulation links. Because of the large area, it is usually necessary to lay ventilation pipes to prevent the ground frost and forklift need to go and out. When laying XPS panel, it is usually necessary to lay 150 mm to 200 mm thick XPS panel in low temperature cold room and 100 mm to 150 mm thick XPS panel in high temperature cold room.

At the same time, it also needs to lay moisture-proof and vapor-proof material (like SBS material ) on the top and bottom of XPS panel. And then reinforced concrete is usually at least 15 cm thick. Carbonaceous or epoxy floors should be made according to the requirements. Usually, it is recommended to make diamond floor for cryogenic storage.

If you do not know how to make ground thermal insulation for your cold room, welcome to contact us.

Post time: Apr-24-2022